Surveyor

SURVEYOR is a pre-study (6-month) project aimed at improving the work space in foundries by using a better ventilation surveying approach. While indoor ventilation is critical due to the health and safety concerns associated with ambient air quality, current surveying techniques are overly simplistic and do not provide plant operators and occupational health specialists with accurate information regarding indoor airflow.

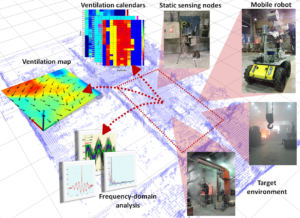

We present a system that addresses the need for better ventilation surveying techniques. Rather than relying on sporadic measurements and simplistic models, the proof-of-concept system in SURVEYOR addresses ventilation surveying using a mobile robot, static sensing nodes and advanced statistical modelling algorithms. The robot and the sensing nodes provide complementary view s of the airflow patterns inside the foundry at different temporal and spatial resolutions. The “ventilation maps” produced by SURVEYOR are statistical models that predict the airflow conditions (w ind speed and directions) over the entire foundry. Ventilation studies at such level of detail are not produced by current characterization techniques. SURVEYOR w ill be developed at Örebro University, which is a lead research institution in environmental-monitoring robotics. Johnson Metall, Scandinavia’s largest manufacturer of bronze bearings, and Global Castings Guldsmedshyttan, a global supplier of heavy cast-based components for the w ind pow er industry w ill support the project from the standpoint of an end-user.

SURVEYOR is funded by the strategic innovation programme STRIM (Strategic innovation programme for the Swedish mining and metal producing industry), which is part of a joint investment in strategic innovation areas (SIP) by Vinnova, Formas and the Swedish Energy Agency.

NEWS

2019-03-06

SURVEYOR to be present in Metalliska Materials’ programsdag

On March 6th, 2019, SURVEYOR will be part of the talk “Innovative A.I in foundries”. The talk will be held in the session “AI as an enabler”, in the programsdag meeting of Metalliska Materials.

Metalliska Materials is an strategic innovation programme from Vinnova’s, the Swedish Energy Agency’s and Forma’s investment in strategic innovation programs and brings together Sweden’s metal industries: steel, aluminum, cemented carbide, cast steel, cast iron and cast non-ferrous metals. You can find more information about the “AI as an enabler” session in particular and about Metalliska Materials in general here.

2019-02-26

Journal article recently accepted!

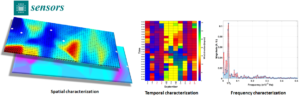

The paper “Multi-domain airflow modelling and ventilation characterization using mobile robots, stationary sensors and machine learning” was accepted for publication in the Sesors MDPI journal. In the paper, we present the Surveyor system, which is composed of static, continuously sampling sensing nodes, complemented by localized measurements, collected during occasional sensing missions with a mobile robot. The article introduces a novel, data-driven, multi-domain airflow modelling algorithm that estimates (1) fields of posterior distributions over wind direction and speed (“ventilation maps”, spatial domain), (2) sets of ventilation calendars that capture the evolution of important airflow characteristics at measurement positions (temporal domain), and (3) a frequency domain analysis that can reveal periodic changes of airflow in the environment. We tested our systems at the facilities of our partners Johnson Metall AB and Global Castings AB. You read the paper and the cool results from SURVEYOR here.

2018-11-09

Project wrap-up

After 6 months of develoment, data collectionm robotics, machine learning and mountains of dust, SURVEYOR has concluded. Örebro University, Johnson Metall and Global Castings sat together to discuss and analyze the results. The main conclusion was that SURVEYOR provides information that is not possible with currently used ventilation systems. Moreover, potential cost-saving benefits from using the SURVEYOR system were identified. For example, studies can be conducted before making costly changes to the ventilation systems. The models produced by SURVEYOR can then be used by decision-making specialist to determine whether or not ventilation changes are actually needed.

2018-10-17 to 2018-10-25

Measurement campaign at Global Castings AB

The SURVEYOR system was deployed at Global Castings to collect data in the foundry hall. After one week of continous, 24h measurements with the sensing node, data is now ready to be evaluated. Notice the amount of dust accumulated on top of the sensor boxes. Foundry inspection requires robust measurement devices, something that SURVEYOR can provide!!

2018-09-06 to 2018-09-17

Measurement campaign at Johnson Metall AB

The SURVEYOR system was deployed at Johnson Metall!! After a few setbacks with the robot localization system we were finally able to perform measurement tours. Our sensing nodes were able to collect data uninterruptly during the full deployment. Many thanks to Sai Lokesh for his help on the design of the firmare. In total, we collected 36GB of data. Now, time to run some data analysis.

2018-08-10

The SURVEYOR prototype is finally ready

This has been a very busy summer but finally, the SURVEYOR system has been built and tested. The prototype was deployed at the newly-built Robolab at Örebro University. The Robolab aims to replicate an industrial setting for robotics applications, in particular logistics applications. After exhaustive testing, the prototype is ready to travel to the dusty, complex foundry environments!

2018-05-01

SURVEYOR kicks-off

According to the project plan, this is the first day of the development cycle of SURVEYOR. Plenty of work to do an many exciting challenges to address. Special thanks to our industrial partners Johnson Metall AB and Global Castings AB. Soon we will be at your foundries performing ventilation characterization!